BTOD proudly uses particle board from Arauco on the work surfaces of the VertDesk v3. Working together with K&A Mfg. to create the VertDesk v3, particle board from Arauco is shipped in and customized to fit each individual desk. Once they arrive, the boards are cut into specific shapes and equipped with starter screw holes to install the surfaces to height-adjustable table bases.

Full Disclaimer: We are an office furniture dealer and sell some of the products we review. To learn more about the products we sell, our review process and why you can trust us, please visit: Why we’re different. Who is BTOD.com and The Breakroom Blog?

Arauco Particle Board & Lamination

- Arauco Facility in Michigan

- Raw Material

- Mill & Dry

- Former

- Press

- Cooler

- Lukki Storage

- Sand & Saw

- Laminate Line

Arauco’s particle board and lamination facility is the largest of its kind in North America. This $500,000,000 facility, located in Grayling Michigan, is one of the most advanced in the world, with all raw materials coming from forests within a 70-mile radius. Sustainability is major priority for Arauco and they’ve worked hard to train local logging companies to be FSC (Forest Stewardship Council) certified. Starting with only two loggers in the area, Arauco has expanded its reach to over 50 loggers.

When the logs come into the facility, they are placed onto a log deck and fed into a chipper to break down into the ideal particle size. The chips are organized into hard or softwood and prepared for pickup by truck. When the trucks drop off the chips, they take a sample of the batch so they exactly what they’re getting and where it came from. Once the chips are dropped off, they are moved to a raw material aging building and placed through a conveyer system where the chips are sorted by particle size. They are then separated by fine or flake sized chips and kept in separate silos.

Once the flake sized chips are moved into the flaker building, they are shaved down to the optimal size. Shape, and weight. The process consists of the chips be dropped onto a large spinning wheel that slowly breaks the fiber down into the precise size and strength for building particle board.

After the chips are broken down, a conveyer belt carries them from the flaker building to the dryers and then to the screener building. The final screening process ensures that each particle is the right size in both the fine and flaked form. In this process, the particle falls through screens designed to separate the particle, so all is correctly sized.

As the dried material comes into the next building, it falls through a dowsing system, covering the material in resin as it falls. The resin holds particles together when heat and pressure are applied. As it enters the former, the particle is separated into two outer surface layers and one inner core layer. The surface layers cover the outer sides of the particle board and are made with fine grain material. This is done so that if you need to router or sand the particle board, your finest, tightest material will be on the outside. The core material is made up of long, stringy fibers. As material comes out of the former, you can see the separation between the top and bottom face as well as the fluffier core material.

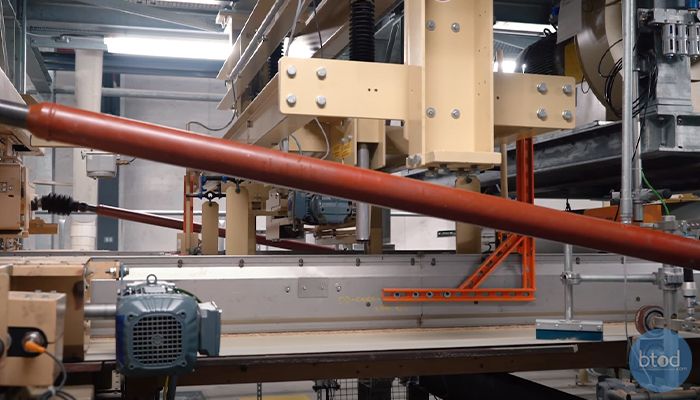

Arauco is home to the largest continuous press in North America, standing at 52.5 meters long. As the particle moves from the former to the press, the air is pushed out of it making the mat much flatter and narrower.

The board is then placed into the press so it can be continuously expanded and contracted. As it runs through different sections of the press, is met with different temperatures and pressures ratios so the resin sets evenly throughout the entire board. At the end of this process, the board is cut into sections and observed to ensure quality.

Once the board is approved, it’s moved onto cooler. This massive machine consists of six wheels that spin to get the boards down to a workable temperature so it can be stacked. Up to 270 master panels (boards) can be loaded onto the massive cooling wheel at once as it rotates and cools the boards to the appropriate temperature.

The Lukki is an automated board storage retrieval system. Panels fall into the system and are stacked into square bundles. These bundles are held in the storage system until they are ready to be moved to the next step of production. The Lukki system is programmed to transport up to 192 pallets of raw boards between storage and the sanding/sawing area.

When the panels are ready to be sanded, they are taken over to the sanding booth and each panel will be sent into the sander individually. Here, high speed sanders locate and remove uneven spots from the boards surface. When completed, the Lukki takes the panels over to the saw line, where they will either be ripped or crosscut, creating panels with exact width and thickness. When this step is complete, they are put in bundles to be sold as raw boards or taken over to the thermally fused laminate line.

When the laminate is applied to the raw board, it is thermally fused on, meaning there is no stick, and it cannot be removed from the board. The system evenly distributes heat over the board for consistent gloss over the entire board. This machine is capable of laminating up to 450 panes per hour with 80 different design options, and multiple textures.

Final Thoughts

Arauco’s state of the art facility combined with sustainable use of forest resources makes them a juggernaut in the particle board and laminate industry. Not only do they serve customers in their industry, but they’re important to the state of Michigan where they’re located. Creating economic benefits by utilizing efficient consumption of regional forest resources and working with local loggers and manufacturers is something they look forward to continuing in the future.